Pre-Shipment Inspection (PSI) for Quality Control before Shipment

Ensure your products meet your requirements before the production run is finished and your products are packed for shipment.

QIMA’s pre-shipment inspection is an intensive on-location examination conducted when 80% of your production order is complete. Our service helps you check if your products meet all required specifications, allowing you to take corrective actions before your production order is finalized.

Learn more about:

What is a Pre-Shipment Inspection (PSI)?

Why Do You Need a Pre-Shipment Inspection?

What Checks are Carried Out?

QIMA’s Pre-Shipment Inspection (PSI)

What Happens after a PSI is Completed?

QIMA Expertise

Trends & Insights in Pre-Shipment Inspection

QIMA Pre-Shipment Services

QIMA Benefits

FAQ

What is a Pre-Shipment Inspection (PSI)?

A pre-shipment inspection ensures your products meet your quality specifications before they are shipped. When at least 80% of your order is complete, an inspector visits the factory and uses industry-standard processes to comprehensively review and test your product. You’re provided with a full report, accessible through our online platform.

Need more information?

By contacting QIMA you agree to our privacy policy and terms and conditions.

Why Do You Need a Pre-Shipment Inspection?

Pre-shipment inspections conducted by a neutral third party are industry standard for ensuring your product meets your quality specifications. Defective or subpar products could lead to customer complaints, returns, lost sales, and damage to your company’s reputation.

With our pre-dispatch inspection, you get peace of mind that your order has been fulfilled correctly before shipping.

There are several reasons to use our PSI:

Ensure that your supplier has met all agreed-upon specifications: This helps to prevent misunderstandings and ensures that the products delivered are exactly what was requested.

Verify quality standards with off-the-shelf or custom checklists: Custom checklists can be tailored to your specific needs based on your unique criteria.

Check production progress: Identify any delays before they impact your delivery schedule.

Take corrective action before it’s too late: Implement solutions promptly, minimize disruptions to production and shipping.

Prevent returns and protect your brand’s image: By ensuring quality before shipment, you reduce the likelihood of customer complaints and returns.

Verify final product quality when you can’t access the factory yourself: With our PSI, you can maintain quality assurance without being physically present.

It’s risky to rely solely on your factory to tell you that the products meet all specifications. Our PSI experts will provide an unbiased, thorough assessment of your production order.

How PSI Supports Your Logistics & Shipping Process

A robust PSI doesn’t just protect product quality, it strengthens every step that follows in your supply chain. By confirming packing, carton specifications, quantities, and shipping marks before dispatch, PSI helps ensure your goods are ready for efficient handling by your logistics partners.

A completed PSI can help you:

Prevent shipping delays caused by incorrect packing, labeling, or product discrepancies.

Support freight forwarders with accurate weights, carton dimensions, and verified quantities for cargo booking and planning.

Facilitate smoother customs clearance by reducing the risk of non-compliant labeling or packaging.

Avoid re-work after shipment, which delays delivery and increases transport costs.

Reduce damage in transit by validating packaging integrity and export carton standards.

PSI acts as a final safeguard that your products are ready for international transport, minimizing surprises once your shipment enters the freight network.

What Checks are Carried Out?

The QIMA inspector will first randomly select a sample of products for inspection, following the ANSI/ASQ Z1.4-2008 sampling standard.

After the sample has been selected, the inspections are tailored to fit client needs and specific products.

We provide a variety of pre-designed inspection checklists suitable for different products, which you can use "as-is." You also have the option to modify these checklists by adding particular checks, or you can develop a completely new checklist that caters to your specific requirements.

QIMA’s Pre-Shipment Inspection (PSI)

QIMA conducts a comprehensive PSI that involves a series of meticulous checks, typically including the following:

Product specifications checks:

Quantities of semi-finished, finished, and packed products

Product colors, style, construction

Artwork including spelling, fonts, dimensions, positioning, design

Main labels, care labels, size labels, product tags

Other product-specific checks and tests

Functional testing

Material composition check

Other relevant tests

Workmanship defects checks

Imperfections check

Assembly process check

Consistency across all products

Product dimensions check

Length, width, height

Unit weight check

Packing and packaging checks:

Inner and outer unit packing

Export carton dimensions and weights

Shipping marks on cartons

What Happens after a PSI is Completed?

Following the inspection, you receive a detailed report the same day. This report includes:

Inspection findings

Photos of any defects

A clear pass/fail assessment

Verified carton details, quantities, and packing information your logistics partners may rely on for transport planning

You can access the report instantly through your myQIMA account.

QIMA Expertise

QIMA provides independent quality control designed to protect your business interests. Our highly trained and experienced inspectors are product experts who undergo regular training in their field of specialization. They can be on-site at your factory within 48 hours of booking and provide the report on the same day as the inspection.

Our inspections cover a full range of consumer products, including but not limited to apparel, footwear, toys, electronics, and furniture.

Create an account and book a PSI

Take your quality management online

QIMA offers an intelligent online platform to help you seamlessly manage your quality control and global supply network.

With just a few clicks, you can:

Book, cancel, or reschedule inspections

Make payments

Access or download your inspection reports

Have full visibility into your supply chain performance through a customizable dashboard, allowing you to identify trends and make informed, real-time decisions.

Trends & Insights in Pre-Shipment Inspection

Rising Importance: The third-party inspection market is expanding rapidly. Projected to reach nearly USD 2.8 billion by 2035, it suggests increased reliance on services like PSI. Brands are now making PSI a standard part of global sourcing, not just a nice-to-have.

The High Cost of Poor Quality: Quality failures can eat up 15-20% of revenue through scrap, returns, re-work and brand damage. For example: skipping a PSI on a USD 430K order with a potential 20% defect rate could expose you to USD 86K of losses - compared to only ~USD 1K for an inspection.

Defect and Supplier Trends: Low supplier engagement correlates with 32% more critical defects, and 60% of those slip past final inspection. Brands using regular independent PSIs often see defect reductions of 10-15%.

Digital & Data-Driven Quality: Inspection services are getting smarter: digital platforms, remote tools and analytics now help track supplier performance and shipment readiness. QIMA’s platform supports this shift, enabling proactive quality management, not just reactive checks.

Strategic Take-away: Integrating pre-shipment inspections into your supply-chain process helps you:

Control quality-related costs

Reduce defect and recall risk

Power more reliable logistics and delivery outcomes

Frequently Asked Questions (FAQs)

1. What is a Pre-Shipment Inspection (PSI)

A pre-shipment inspection is a detailed, on-site product review conducted when at least 80% of an order is complete. It verifies product quality, specifications, labeling, packaging, and quantity before the goods leave the factory.

2. Why is a PSI important?

PSI helps you catch defects before shipment, reduce the cost of poor quality, protect your brand reputation, avoid returns and delivery delays, and ensure products meet both your specifications and regulatory requirements.

3. When should I schedule a PSI?

A PSI should be booked when your production is 80% finished and packing has begun. This timing allows enough product to be available for sampling while still leaving room for corrective action.

4. What does a PSI typically check?

The inspection covers:

Product appearance, construction, materials, and safety

Workmanship defects

Product dimensions and weights

Labeling, tags, markings, and compliance information

Packaging and export carton details

Functional and on-site performance tests

Quantity and assortment verification

All checks follow international sampling standards (such as ANSI/ASQ Z1.4).

5. How does a PSI help my logistics and shipping process?

A PSI confirms that packaging, carton weights, labeling, and shipping marks meet export requirements, reducing customs delays, avoiding re-packing, improving cargo planning, and ensuring freight forwarders receive accurate data for booking and transport.

6. How long does a PSI take?

Most inspections take one full day on-site. QIMA inspectors can typically be at the factory within 48 hours of booking, and you receive your report the same day the inspection is completed.

7. Do I need to be present during the inspection?

No. QIMA conducts unbiased inspections on your behalf. You receive detailed photographic evidence, test results, defect listings, and a clear pass/fail assessment via your online platform.

8. What happens if the PSI fails?

You can work with your supplier to correct the issues before shipment. Many clients request a re-inspection after corrective actions are taken to confirm that the improvements were made successfully.

9. How are products selected for inspection?

Inspectors randomly select samples using statistically valid sampling plans (ANSI/ASQ Z1.4). This ensures an objective, representative evaluation of your order.

10. Can I customize the inspection checklist?

Yes. You may use QIMA’s pre-designed checklists, modify them, or create completely custom checklists to match your specifications, regulatory requirements, or brand standards.

11. How do PSI results support ongoing supplier management?

Inspection data reveals patterns such as recurring defects, inconsistent workmanship, or non-compliant packaging. Over time, this helps you identify high-performing suppliers, track improvement trends, and address root causes of quality issues.

12. How does QIMA ensure inspector expertise and neutrality?

Inspectors undergo continuous training, specialize in specific product categories, and operate with strict independence. QIMA does not manufacture or trade goods, ensuring no conflict of interest.

13. What industries benefit most from PSI?

PSI is widely used in:

Consumer goods (apparel, footwear, accessories)

Toys and children’s products

Electronics and electrical appliances

Homeware, furniture, and décor

Industrial goods and components

Any product with brand, safety, or compliance risk benefits from PSI.

14. How does QIMA’s online platform support quality and logistics workflows?

You can book and manage inspections, view reports, analyze supplier performance, identify defect trends, and access historical data in real time—helping you make more informed sourcing decisions and improving supply-chain reliability.

15. Does a PSI replace laboratory testing?

No. PSI evaluates the finished goods visually and functionally. If your product requires compliance testing (e.g., chemical, mechanical, or safety standards), you should combine PSI with accredited lab tests.

16. How much does a PSI cost?

Pricing depends on product type, location, and inspection scope. However, PSI is a small investment compared to the potential cost of defects, rework, delayed shipments, customer returns, and reputational damage.

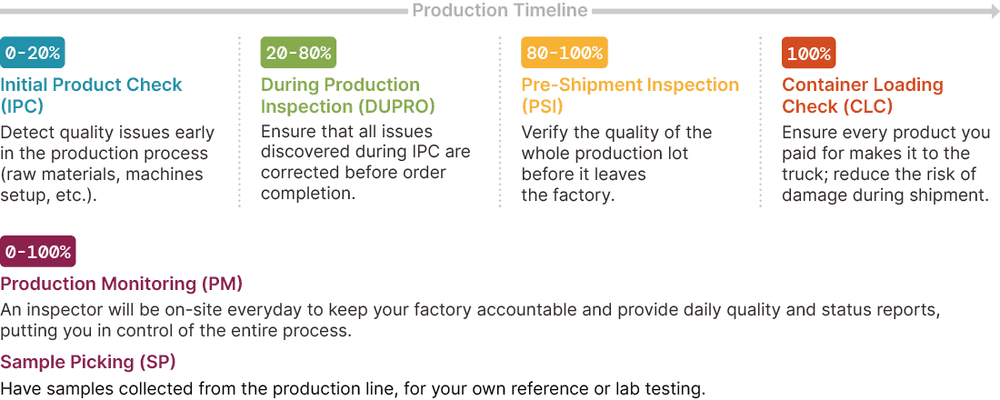

17. Can I integrate PSI with other quality services?

Yes. Many companies combine PSI with:

Factory audits

During production inspections (DUPRO)

Container loading checks (CLC)

Product testing

This creates stronger end-to-end quality assurance from raw materials to shipment.

18. Is PSI necessary if I trust my supplier?

Even reliable suppliers can face production variability, workforce turnover, raw-material changes, or equipment issues. PSI protects your supply chain from preventable surprises and gives you verified data instead of assumptions.

QIMA Benefits

Independent quality control performed by product experts to protect your business interests.

Global coverage across 100 countries in Asia, Africa, Europe, North and South America.

Speed and flexibility with an inspector onsite within 48 hours; modify or cancel up to the day before inspection.

Same-day inspection reports tailored for your product.

Online program management to book inspections, make payments, and download detailed reports.

Custom quality dashboard to identify trends and make informed decisions in real time.

Ranked #1 in the industry for customer satisfaction based on independent NPS measurement.